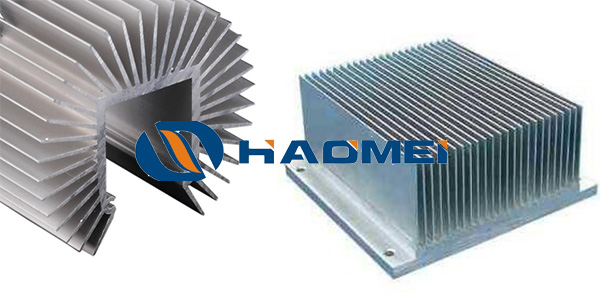

Heat sink extrusions are taking up an increasing share of metal market all over the world, especially this year, when the winter seems to be colder in the Northern Hemishpere than previous years. It’s said that some colleagues in southern China have taken winter holidays in advance because of unusual coldness. Generally speaking, there are two types of heat sink extrusions in the market: steel and aluminum extrusions.

Although many people would like to choose steel for their, aluminum extrusions have obvious advantages over steel ones. First, they shows better heat dissipation property and are therefore more energy-saving. Less amount of aluminum heating plates are needed in the same room to reach the same heat dissipation effect. Second, aluminum heat sink extrusions prove to be more corrosion resistant than steel ones to which anti-rust additives must be added. The element of aluminum is so active that it produce a layer of oxide easily after being exposed to oxygen in the air. The layer, strong and dense, protects effectively the covered body against corrosive materials. Third, if you choose combined type of aluminum heat sink extrusions processed by high-pressure casting aluminum module, you will enjoy two bonuses. This type of plates have been pressure cast overall by a single process, and there will be no potential problems like water leakage when you use them. Besides, extra plates can be added directly to the original module if necessary, with no need of replacing the whole module as steel plates would have.

In spite of the advantages of aluminum heat sink extrusions above, customers should avoid to mix aluminum plates with those of other metals like steel, because they have different requirements for water quality. Haomei Aluminum supplies aluminum extrusions of varied specifications. Welcome to contact us at april@aluminumhm.com, leave a message below or wechat/whatsapp 008615838029491 for more information.